Did you know most scaffolding containment and encapsulation products are made of plastic such as polyethylene that will melt and burn when subjected to heat?

This represents a huge risk should there be any sort of ignition source near the encapsulation. Heat and flames in a short time can spread right up the side of a scaffold, and it does not stop there. As the flames are then driven along the scaffold deck, falling burning droplets of plastic will ignite anything below that is not yet burning. A nightmare scene that no site wants to see! However, it has happened before and while flammable scaffold encapsulation products are still used in Australia it could happen again – don’t let it be on your site!

The danger of scaffold fires caused by non-FR containment products has resulted in the Australian Standards committee drafting a new encapsulation standard requiring all scaffold containment products to be Fire Retardant.

<br>

What is FlameX?

Safety is our number one priority in every product, that is why Sitemax has offered the FlameX fire retardant containment range for many years now. Putting it simply FlameX is an additive that is mixed into the formation of the polymer that reduces its flammability to the point it will not self-combust.

FlameX is available in scaffmesh scaffolding mesh, Scafclad environmental encapsulation and bannermesh categories meaning that your sites can be wrapped and branded both safely and risk free. FlameX will help mitigate risk on your worksite, meaning you can have confidence that your team will go home safely.

The more plastic (fuel) in a product, the more fire-retardant additive that is needed. However, when fire retardant additives are included in plastic products, this immediately reduces the UV stability which is a critical issue in our Australian weather conditions. The useable lifespan of a plastic FR containment product will be drastically shorter than a non-FR plastic product.

<br>

So, what is the answer?

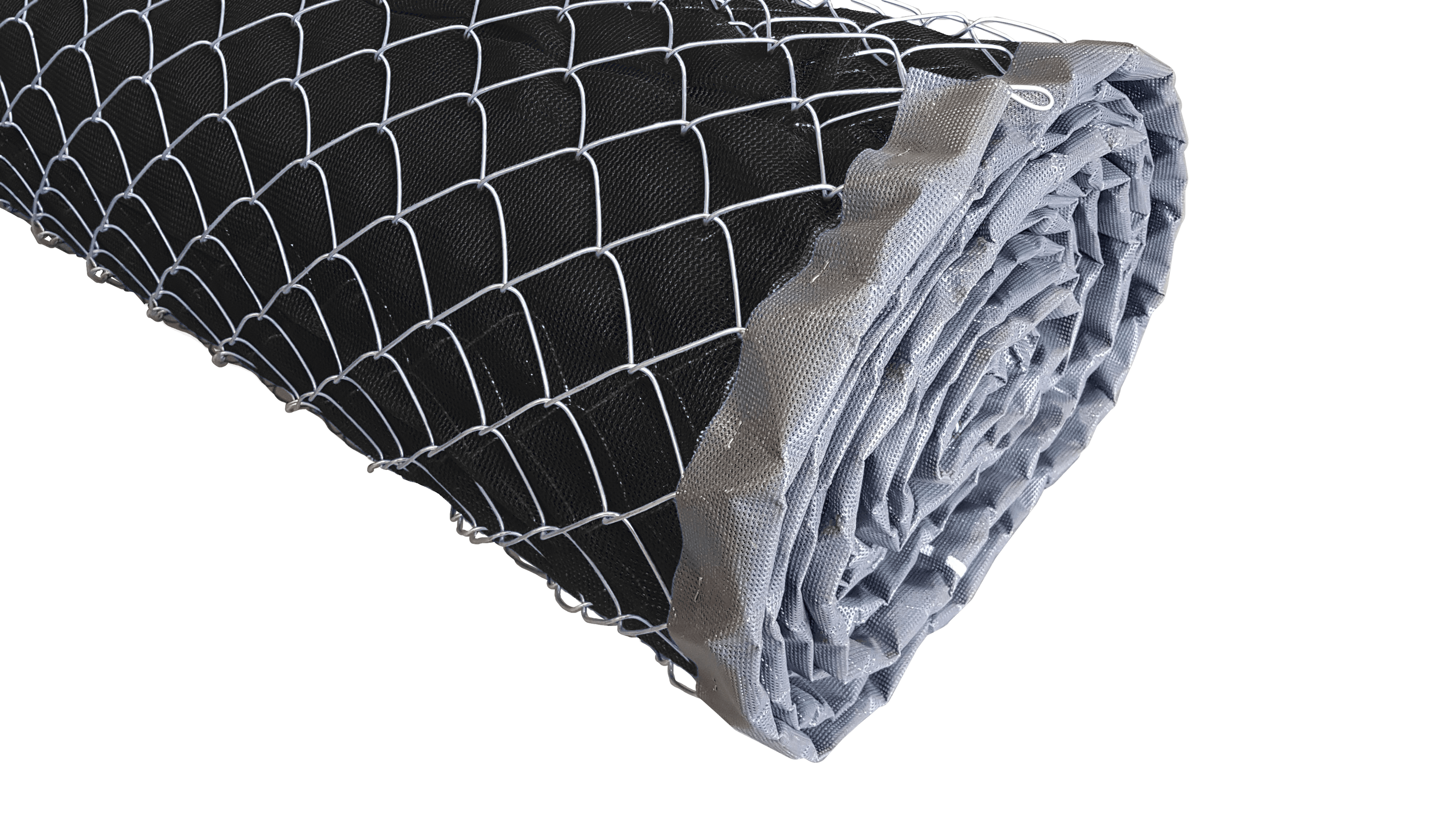

The ideal solution is the Sitemax Spidermesh, known for how easy it is to roll out and roll up.

The lining is also replaceable, so your job will look like new every time. The base material is steel, meaning you don’t have to worry about compliance or strength degrading in the sun. Finally, Spidermesh is recyclable!

Contact the team at Sitemax today on 1800 007 557 or sales@sitemax.com.au to discuss your requirements!